3D technology can be utilized in manufacturing to improve a variety of processes, including design, prototyping, training, and quality control. Scanfil is piloting 3D technology in its expansion project in Atlanta. Utilizing VR and 3D technology in a manufacturing environment can help to improve the efficiency and effectiveness of a variety of manufacturing processes, while also helping to reduce costs, improve quality, and increase customer satisfaction.

Scanfil is piloting 3D technology in its Atlanta project

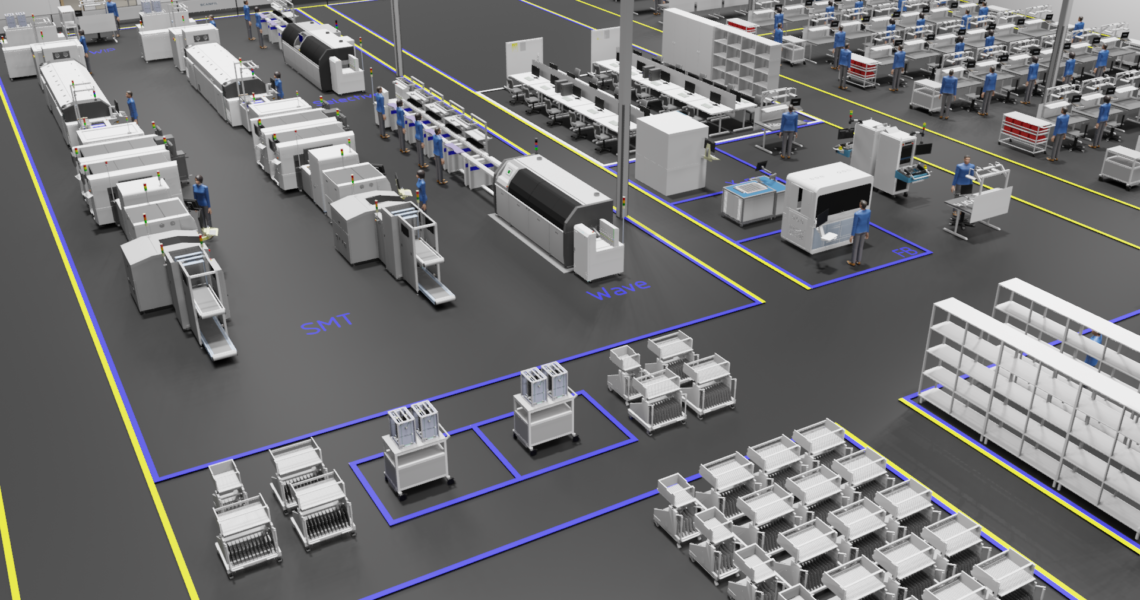

Scanfil has utilized 3D technology in its expansion project in Scanfil Atlanta. The decision to utilize the 3D technology stemmed from the need to address issues of misalignment and misinterpretation that arose due to team members located in multiple countries and working with 2D layout drawings.

“I had experience utilizing 3D tools in similar projects in the past, so I proposed making this a pilot project to gather some experiences and assess the benefits. This type of tool has not been utilized in our company before, so this is more like a pilot to gather experiences and opinions on the process,” explains Miikka Ahola, Director of Manufacturing Technology.

Using 3D technology aids in visualizing and bringing plans to fruition

The utilization of 3D technology has helped in the layout and planning stages of the project. The detailed plans created with 3D technology have allowed for a better indication of needs and improved process flow.

The project has been moving forward quickly. It started in November 2022, and the team is planning to have the first stage ready already in January 2023. According to Miikka, they are exploring the possibility of creating simulations of material flow in later stages.

The benefits of 3D technology in the Atlanta expansion project have been clear. “We can easily go through the changes in plans remotely, so this reduces the need for traveling during the planning stage. Also, the marketing and even production operators, that don’t have deep knowledge of the machines, can easily understand the plans, and see the working environment we are setting up”, says Miikka.

The future of 3D in the manufacturing industry seems to be promising

After the pilot project, our team will share views on how this has affected our way of working and possible future benefits. “There is still a lot of potential to be utilized in the future with simulation and testing new technologies in a virtual environment,” says Miikka and continues “Also, doing NPI and proto builds in a simulated virtual environment before having actual parts is an interesting concept”. Overall, the future of 3D in the manufacturing industry and in Scanfil appears to be very promising.