Our Dream Factory

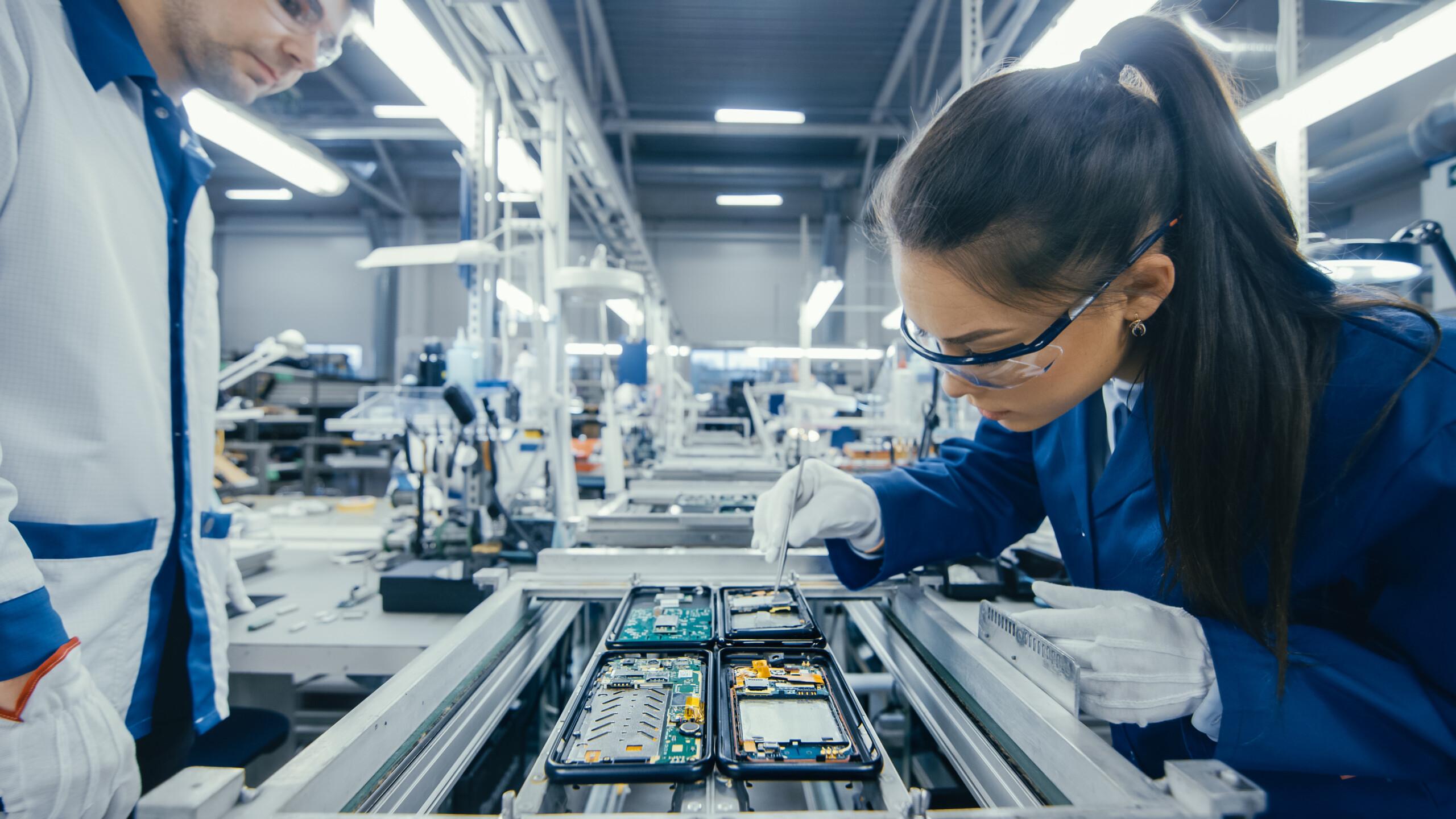

The Dream Factory concept aims to achieve top-tier competitiveness and customer satisfaction through operational excellence. It focuses on optimizing factory performance by connecting people, processes, and equipment with real-time data and AI. The program emphasizes digitalization, automation, and the use of modern tools like eDHR for creating and sharing instructions.

The ultimate goal is to develop a multi-skilled workforce that operates seamlessly with advanced technologies, leading to unparalleled operational excellence and a future where factories are highly efficient and effective.

Smart Technology

Smart Technology emphasizes value-driven automation, which focuses on enhancing efficiency and productivity. It is AI-assisted and connected, ensuring seamless integration and intelligent decision-making. Additionally, it offers universal and flexible solutions that can adapt to various needs and environments.

Digital Flow

AI & data foundation involves building a robust data infrastructure powered by AI. Advanced planning and scheduling optimize production schedules with advanced algorithms. Real-time data visibility ensures transparency and immediate access to critical data. AI-assisted quality control leverages AI to maintain high-quality standards. Traceability tracks every step of the production process for accountability. Workflow optimization streamlines workflows to enhance efficiency.

Factory Flow

Optimizing WIP, layout, space, movements, and utilization ensures efficient use of resources and space. Shop-floor visual management involves implementing visual tools to manage shop-floor activities. Dream Factory production line concepts focus on developing innovative production line designs.

Workforce

A multi-skilled and agile workforce involves cultivating a versatile and adaptable team. Upskilling and scaling with Lean Six Sigma enhances skills through continuous improvement methodologies. Continuous improvement and problem solving foster a culture of ongoing enhancement. Digital skills development equips the workforce with essential digital competencies.